Easy to install, easy to maintain, the MagnaClean DRX offers facility managers, specifiers and installers a more budget-friendly option for eliminating iron oxide sludge in hydronic heating systems.

The ADEY® MagnaClean™ DRX magnetic dirt filter provides a highly compact and cost-effective solution for removing debris and black iron oxide sludge from commercial hydronic heating systems. Available for roughly 60 percent of the cost of premium magnetic filtration products, the DRX offers essential magnetic filter technology to engineers and other specifiers who are reluctant to use such a product because of budget constraints.

“Unfortunately, filters and other water-treatment products are often the first items to be dropped from the specification when building owners and hydronic system designers need to cut costs,” says Neil Watson, Chief Technical Officer for ADEY Innovation LLC. “But facility managers, who must cope with the consequences of iron oxide damage daily, recognize the hard-dollar value of magnetic filtration in the form of fewer costly repairs, fewer system breakdowns and reduced capital equipment-replacement expenditures.”

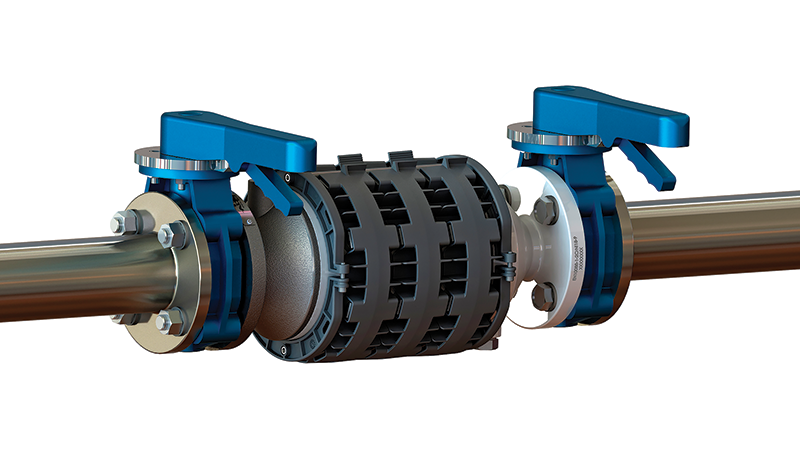

In addition, its compact and versatile design — which allows it to be installed in-line or side-stream and in either a vertical or horizontal orientation — makes it an ideal solution for maintenance or renovation applications where mechanical-room space is limited.

Innovative design and construction: Based on industry-proven magnetic filtration technologies and components and built to ASME standards, the MagnaClean DRX consists of an external magnetic belt, containing dozens of high-performing neodymium magnets, wrapped around a precision-engineered, stainless-steel canister. As system water passes through the canister, iron oxide is captured by the intense magnetic field. Magnets remain outside the flow, so there are no internal sleeves or components that must be removed and individually cleaned.

In an in-line installation, the iron oxide sludge can easily be drained when the system is shut down, the magnetic belt released, and the drain valve opened.

With no moving parts inside the canister, the quick-release belt makes it easier to install and service the unit. In-line installation eliminates the need to put the system on bypass to complete maintenance.

The MagnaClean DRX is available in 2-inch (with 48 magnets), 3-inch (64) and 4-inch (80) pipe dimensions, with the multiple magnets ensuring effective magnetite capture through the canister’s stainless steel wall. Each filter comes supplied with EDPM full-flange gaskets for robust sealing at high temperatures.

Other key features include:

- Near-zero pressure drop: While removing virtually all magnetite, the patented design of the MagnaClean DRX puts nothing in the flow pattern of system water. This ensures that the filter does not negative impact the heating system’s ability to meet demand. As a result, the versatile DRX can be installed inline or side-stream and in either a vertical or horizontal orientation — whatever the system requires, whether new or retrofit.

- Spring-loaded magnets: This feature ensures that the magnets align properly with the canister, maximizing capture.

- Lightweight: Weighing only 11 to 18 pounds, all three MagnaClean DRX models can be installed by a single mechanic, reducing manpower without sacrificing installation speed.

- Press-fit installation also allows for faster, easier installs in both new and retrofit applications.

- Small footprint: Suitable for mechanical rooms where space is limited.

Why magnetic filtration? Removing iron oxide is essential, since up to 95 percent of all hydronic system debris is composed of this substance. The average size of an iron oxide particle is only eight microns, or roughly one-sixth the width of a human hair — too small to be effectively captured by mesh strainers or basket filters. The problem is compounded in ECM (Electronically Commutated Motor) pumps whose magnetic-drive components actually attract the iron oxide.

If not captured and eliminated, iron oxide buildup can drastically reduce system efficiency. Heat transfer can drop by as much as 15 percent, while boiler efficiency can decline by up to 6 percent after only three weeks, inevitably increasing operating costs for the owner.

Building owners and managers often blame boiler or circulator failure for problems that are actually the result of the accumulation of iron oxide throughout the entire hydronic system. As a result, contractors are forced to perform countless warranty repairs, as time and money are needlessly wasted.

The MagnaClean DRX offers a simple, affordable cure for the most common system problems caused by iron oxide buildup, including poor circulation as well as blocked heat exchangers, pumps and radiators. This helps prevent system breakdowns, expensive repairs and the associated costs of unplanned business closures, while also optimizing the efficiency and minimizing running costs of heating systems.

“By making magnetic filtration technology affordable for virtually any commercial installation, ADEY hopes to change the way industry thinks about water quality in heating systems,” says Watson. “At a time when the use of ECM pumps and high-efficiency equipment is growing due to consumer demand and tighter energy efficiency standards, we believe the MagnaClean DRX can become the catalyst for a better understanding that maintaining water quality is not an option, but a necessity.”